This

summer (2018), arriving early for a movie at the ArtsQuest Center

at SteelStacks https://www.steelstacks.org/

in Bethlehem, Pennsylvania, I was surprised to see the elevated walkway over

the old trestle

right in front of the majestic row of closed Bethlehem Steel blast furnaces

across from the arts venue. (Steel making in Bethlehem ceased in 1995, and the

expansive industrial property along the Lehigh River has been repurposed as an

arts/entertainment/retail center.) The walkway with educational signs about the

blast furnaces and related steelmaking process has been there since about 2013,

but somehow, big events or bad weather kept me from noticing it before.

Not

sure when in my life I first heard of Bethlehem Steel: definitely by the time

my youngest sister attended Lehigh University, an engineering and liberal arts

school, just up the hill from the steel works in Bethlehem. She would mention

the huge completed I-beams that would tie up traffic as they tried to make

their way out of town.

Eleven

years after her graduation, we moved to Easton, immediately east of Bethlehem

and the smallest of the Lehigh Valley’s three cities: Allentown, Bethlehem,

Easton. Although non-local media outlets sometimes call the area “Philadelphia

suburbs”, and many do commute daily 50-60 miles to Philadelphia, we are also 65

miles straight due west of New York City with a significant population

commuting to the “Big Apple”. Scranton/Wilkes Barre in the northern anthracite

belt is ~75 miles north. The Lehigh Valley during colonial and growing

industrialization of the 19th century became an industrial hub due

to river and canal access along the Lehigh and Delaware rivers connecting the

anthracite fields, markets of Philadelphia/NYC, and its own mills and

factories. Steelmaking began in Bethlehem in the mid-1800’s.

Prior

to moving to the Lehigh Valley, we lived in Carbondale, Illinois, where I

worked part-time in the coal petrology lab, Geology Department, Southern Illinois University. The lab director, from whom I also took courses in Coal

Petrology and Advanced Coal Petrology, had worked several years in the

Bethlehem Steel research labs characterizing coals for coke-making and specific

parameters that would well-predict the behavior of a coal in both coke ovens

and the resultant coke in the blast furnaces.

I

was fortunate to get a tour of Bethlehem Steel works in 1990 while it was still

operating. We visited the Basic Oxygen Furnace and a rolling mill, escorted by

a retired employee. And a few years later, on a grad school field trip to

various outcrops of the Late Triassic Lockatong lacustrine black shales of the

Newark basin, we ended up in New Jersey right under the George Washington

Bridge (crossing the Hudson River between New York City and New Jersey) with

Bethlehem Steel boldly stamped on the lower girders of the west suspension

tower.

So

here is a virtual tour of the blast furnaces along the Hoover-Mason Trestle walkway at the eponymous site of Bethlehem Steel.

(All photos without citation are by me.):

|

| Figure 1A: Map- Bethworks master plan (~2013) for transforming the Bethlehem Steel site to arts/entertainment area from http://stream-hugger.blogspot.com/2013/01/going-brown-when-going-green-is-bad.html http://stream-hugger.blogspot.com/2013/01/going-brown-when-going-green-is-bad.html . The blast furnaces are in light brown at the central north of the map, bordering the Lehigh River (click to enlarge). |

|

Figure 1B: Map- Bethlehem Steel works from 1979. Note location of brown-colored ore yard (now Sands Casino), red basic oxygen

furnace on right (now industrial park), red blast furnaces (center).

|

|

| Figure 2: General diagram of a blast furnace operation (Dong, 2008*). |

|

Figure 4: Blast furnace row

looking west. One can see the silver-gray tourist walkway over the remnants of

the Hoover-Mason railroad trestle used to transport materials to furnaces.

Canopy structures at the lower left edge of the photo are part of the Leavitt Pavilion outdoor concert venue.

|

|

Figure 5: Staircase up to trestle

walkway, right in front of blast furnace A. According to AbandonedAmerica, “the oldest furnace is blast furnace A, which was built in

1914. It was rebuilt in 1950 and last ran in 1960. Because of its location

directly beside another blast furnace (B, which ran into the 1980s), active

mill buildings, and a busy mainline railroad, it was never demolished. ‘A’

furnace is notable because it is the only surviving blast furnace in the United

States that still has triple pass stoves”.

|

|

| Figure 6: Looking east from west end of elevated walkway. |

|

| Figure 8: Close-up of walkway, trestle, and old trestle car, looking west toward blast furnace A. |

|

Figure 9: Trestle route map.

The coke works were about 2 1/2 miles ESE of the blast furnaces; the Sands

Casino was built over the old ore pits, half mile east of furnaces (see Figure

1B map).

|

|

Figure 10: Blast furnace

with skip track used for hauling materials to load at top of furnace.

|

|

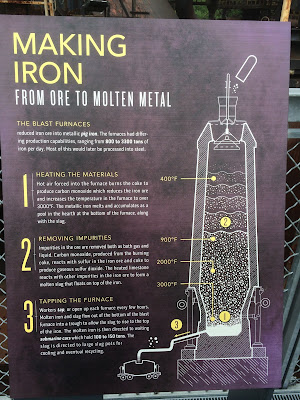

Figure 11: Sign explaining

materials layering in blast furnace and transformation of iron-oxide ore to metallic

reduced pig iron (which has about 4% carbon).

|

|

Figure 12: Working at a

blast furnace, Bethlehem Steel, Sparrows Point, Maryland, 1951 (Baltimore Sun)

|

|

Figure 13: The basic oxygen

furnace (BOF) at Bethlehem. In a BOF, recycled steel or other additives can be

added to pig iron from the blast furnace. The BOF at Bethlehem was just west of the current casino (old ore pit location), but has been demolished,

replaced by an industrial park (see also map of Figure 1B). (Photo: Hagley Museum collection)

|

|

Figure 15: Relict stone

walls of iron foundry (background) and possibly old plate shop (foreground), just

west of blast furnaces. (Based on map 1B and truck dock legend at http://www.brokenbushandroundtop.com/bethlehemsteel/bethmap_page.html

.)

|

|

Figure 16: From 2014, leaving

Christkindlmarkt, an annual German-tradition Christmas craft market in Bethlehem, the “Christmas

City”. For the last several years, the

market has been located at the west end of the “SteelStacks” behind and next to

the Visitors Center.

|

|

|

Figure

17: Blast furnace A illuminated at night.

|

To finish your virtual visit, there is a great DRONE FLYOVER of the SteelStacks from 2016 on YouTube at https://www.youtube.com/watch?v=1HPwX4pB_Qo .

* Citation for Figure 2 diagram: Dong, Shan Ning, 2008, Development of Analytical Methods

for Characterizing Metallurgical Coke and the Injectant Coal Chars, Tars and

Soots Formed during Blast Furnace Operation (dissertation), Department of Chemical Engineering

, Imperial College London of

Science, Technology and Medicine, 204 pages (Figure 2-1) (https://spiral.imperial.ac.uk/bitstream/10044/1/1329/1/Dong-SN-2008-PhD-Thesis.pdf )

No comments:

Post a Comment